Production

-

Mylas

DT series

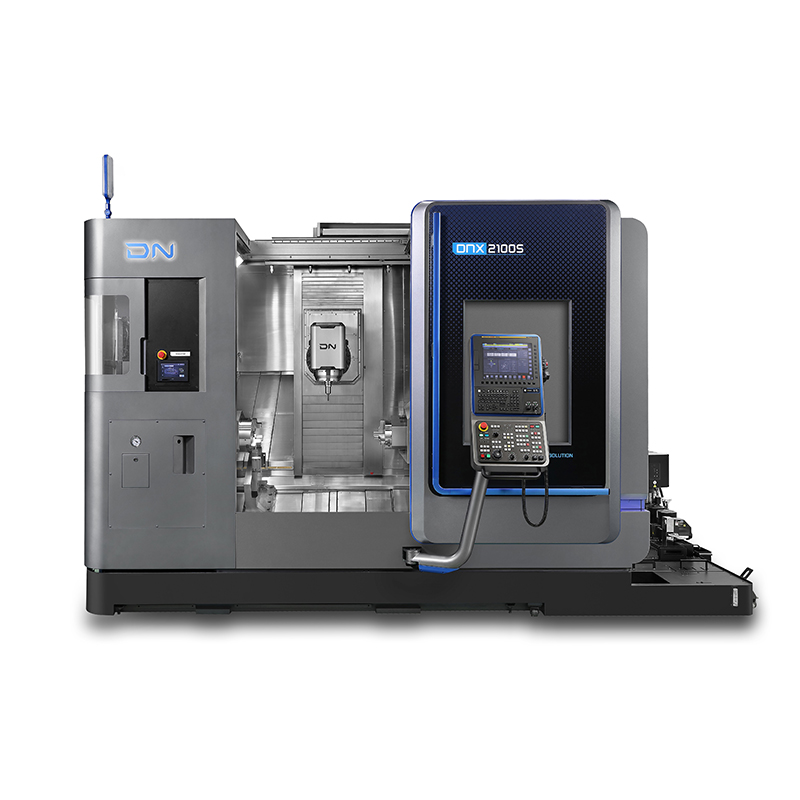

Product Details Close-up of the machine body: Processing performance: This advanced and efficient turning center allows you to complete complex workpiece processing in one device at a time with unparalleled precision. Unlimited potential and multiple performances: The machine is equipped wit...

Description

marker

Product Details

Close-up of the machine body:

Processing performance: This advanced and efficient turning center allows you to complete complex workpiece processing in one device at a time with unparalleled precision.

Unlimited potential and multiple performances: The machine is equipped with dual spindles and turrets, and the back-end processing part has 8 tool positions, bringing the total tool capacity of the machine to 32. It can support a variety of different processing methods with precision.

Front-end processing: BMT 45 12-position power turret, can load up to 24 sets of tools, spindle power 7.5/11 kW.

Back-end processing: Back-end processing with a through hole diameter of 55 mm, VDI 25 8 auxiliary turrets with 8 tool positions, spindle power 3.7/5.5 kW, through hole diameter 48 mm.

Product Parameters

| Processing capacity | Items | Unit | DT42 S | DT52 S | DT65 S | S |

| Chuck type | type | DIN173E | DIN177E | SAD-65 | DIN173E | |

| Maximum cutting length of bar | mm | 135 | 150 | 150 | 60 | |

| Maximum cutting length | mm | 350 | 350 | 350 | ||

| Maximum cutting diameter | mm | 150 | 150 | 150 | 135 | |

| Maximum cutting diameter of bar | mm | Ø42 | Ø50 | Ø65 | Ø42 | |

| Stroke | X1 / X2 axis travel | mm | 175(X1) | 175(X1) | 175(X1) | 240(X2) |

| Z1 / Z2 axis travel | mm | 450(Z1) | 450(Z1) | 450(Z1) | 500(Z2) | |

| Y1 / Y2 axis travel | mm | ±35(Y1) | ±35(Y1) | ±35(Y1) | ||

| X1 / X2 rapid feed | M/min | 18(X1) | 18(X1) | 18(X1) | 18(X2) | |

| Z1 / Z2 rapid feed | M/min | 24(Z1) | 24(Z1) | 24(Z1) | 24(Z2) | |

| Y1 / Y2 rapid feed | M/min | 18(Y1) | 18(Y1) | 18(Y1) | ||

| Spindle | Spindle nose | type | A2-5 | A2-6 | A2-6 | A2-4 |

| Spindle speed | rpm | 50-5000 | 50-4500 | 50-4500 | 50-5000 | |

| Spindle motor (continuous/30 minutes) | kW | 7.5/11 | 7.5/11 | 7.5/11 | 3.7/5.5 | |

| Main turret | Number of tools | set | 12 | 12 | 12 | |

| OD tool holder size | mm | 20 | 20 | 20 | ||

| ID tool holder bore | mm | 25 | 25 | 25 | ||

| Tool change time | sec | 0.1-0.3 | 0.1-0.3 | 0.1-0.3 | ||

| Power tool speed | rpm | 6000 | 6000 | 6000 | ||

| Power tool motor (continuous/30 minutes) | kW | 2.2/3.7 | 2.2/3.7 | 2.2/3.7 | ||

| Power tool torque (Continuous/30 minutes) | NM | 14/23.5 | 14/23.5 | 14/23.5 | ||

| (cont./30mins) | (cont./30mins) | |||||

| Secondary turret | Number of tools | set | 8 | |||

| Outer diameter toolholder size | mm | 20 | ||||

| Inner diameter toolholder size | mm | 20 | ||||

| Tool change time | sec | 0.1-0.3 | ||||

| Power tool speed | rpm | 6000 | ||||

| Power tool motor | kW | 2.2kw | ||||

| Power tool torque | NM | 22 | ||||

| Oil tank | Cutting fluid capacity | L | 250 | 250 | 250 | |

| Dimensions | Machine length | mm | 2600 | 2600 | 2600 | |

| Machine width | mm | 1950 | 1950 | 1950 | ||

| Machine height | mm | 1800 | 1800 | 1800 | ||

| Machine weight | Kg | 5100 | 5100 | 5100 | ||

| Others | Floor area | mm | 4900x3710 | 4900x3710 | 4900x3710 | |

| Electricity requirements | Kva | 55 | 55 | 55 |