Production

-

Mylas

DY series

Product Details Close-up of the machine body: Processing performance: This multifunctional turning center is designed to perform one-time precision machining on complex workpieces. Unlimited potential and multiple performances: This machine is equipped with a dual spindle, a 12-position BMT ...

Description

marker

Product Details

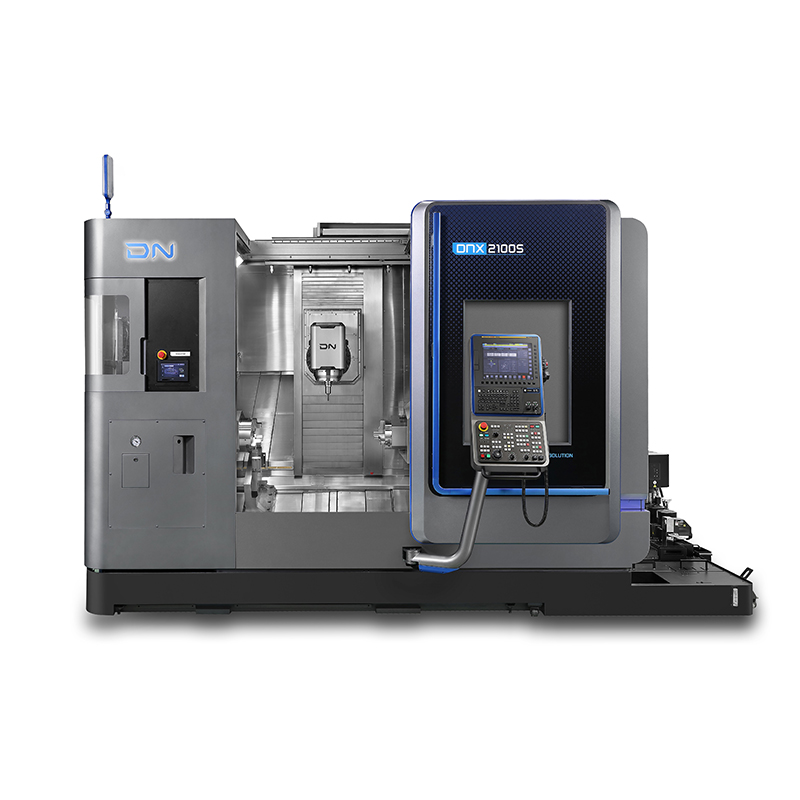

Close-up of the machine body:

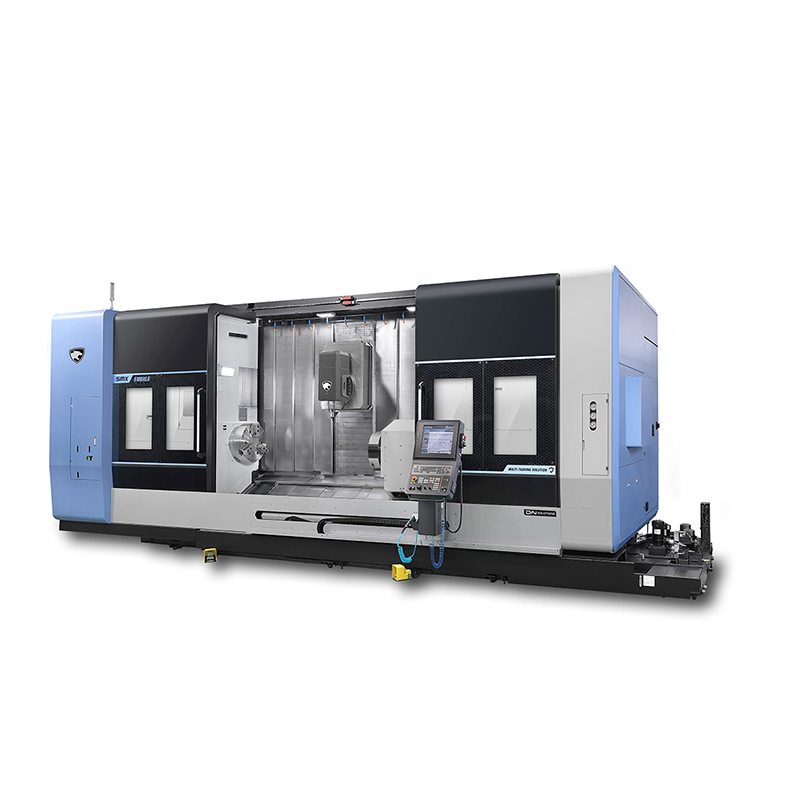

Processing performance: This multifunctional turning center is designed to perform one-time precision machining on complex workpieces.

Unlimited potential and multiple performances: This machine is equipped with a dual spindle, a 12-position BMT turret, and a Y-axis second tool holder for rear face machining, which has 14 tool positions. The total tool loading capacity can reach 38. In addition to enhancing precision, the dual-system turning center mechanism also speeds up production cycles with the dual Y-axis cutting capacity.

Front-end machining: BMT 45 12-position power turret, can load up to 24 sets of tools, spindle power 7.5/11 kW, through-hole diameter 55 mm.

Back-end machining: Multi-tool moving track: can load 14 tools, 3 side power tools, 3 end power tools, 3 outer diameter and 5 inner diameter tools.

Elegant aesthetic design: Mingyang machinery is developed not only to achieve high precision, but also to add a touch of fashion to the workshop with elegant design ingenuity. The sleek lines of this machine series can enhance the operator's pleasure while working.

Mingyang design language: The Mingyang design language set on the machine door is used to remind the operator to open and close the machine door safely. This design image is very eye-catching in the workplace and can specifically feel the fine workmanship of the product.

Product Parameters

| Processing capacity | Items | Unit | DY42 | DY52 | DY60 |

| Chuck type (main/sub-spindle) | type | DIN173E / DIN173E | DIN177E / DIN173E | DIN185E / DIN173E | |

| Maximum cutting length of bar (main/sub-spindle) | mm | 135 / 60 | 150 / 60 | 150 / 60 | |

| Maximum cutting length | mm | 350 | 350 | 350 | |

| Maximum cutting diameter of bar (main/sub-spindle) | mm | Ø42 / 42 | Ø51 / 42 | Ø60 / 42 | |

| Maximum cutting diameter (main/sub-spindle) | mm | 150 / 135 | 150/ 135 | 150/ 135 | |

| Stroke | X1/X2 axis travel | mm | 190 / 260 | 190 / 260 | 190 / 260 |

| Z1/Z2 axis travel | mm | 450 / 500 | 450 / 500 | 450 / 500 | |

| Y1/Y2 axis travel | mm | ±35 / 266 | ±35 / 266 | ±35 / 266 | |

| X1/X2 rapid feed | M/min | 18 / 18 | 18 / 18 | 18 / 18 | |

| Z1/Z2 rapid feed | M/min | 24 / 24 | 24 / 24 | 24 / 24 | |

| Y1/Y2 rapid feed | M/min | 18 / 18 | 18 / 18 | 18 / 18 | |

| Main spindle | Spindle nose | type | A2-5 | A2-6 | A2-6 |

| Spindle speed | rpm | 50 - 5000 | 50 - 4500 | 50 - 4500 | |

| Spindle motor (continuous/30 minutes) | kW | 7.5 / 11 | 7.5 / 11 | 7.5 / 11 | |

| Sub-spindle | Spindle nose | type | A2-4 | A2-4 | A2-4 |

| Spindle speed | rpm | 50 - 5500 | 50 - 5500 | 50 - 5500 | |

| Spindle motor (continuous/30 minutes) | kW | 3.7 / 5.5 | 3.7 / 5.5 | 3.7 / 5.5 | |

| Main turret | Number of tools | set | 12 | 12 | 12 |

| Outer diameter tool holder size | mm | 20 | 20 | 20 | |

| Inner diameter tool holder bore | mm | 25 | 25 | 25 | |

| Tool change time | sec | 0.1 - 0.3 | 0.1 - 0.3 | 0.1 - 0.3 | |

| Power tool speed | rpm | 6000 | 6000 | 6000 | |

| Power tool motor (Continued/30 minutes) | kW | 2.2 / 3.7 | 2.2 / 3.7 | 2.2 / 3.7 | |

| Power tool torque (Continued/30 minutes) | NM | 14 / 23.5 | 14 / 23.5 | 14 / 23.5 | |

| Sub-spindle tool holder | Number of tools | set | 12 | 12 | 12 |

| Outer diameter tool holder size | mm | 16 | 16 | 16 | |

| Inner diameter tool holder size | mm | 20 | 20 | 20 | |

| Power tool speed | rpm | 5000 | 5000 | 5000 | |

| Power tool motor | kW | 2.2 | 2.2 | 2.2 | |

| Power tool torque | NM | 22 | 22 | 22 | |

| Oil tank | Cutting fluid capacity | L | 250 | 250 | 250 |

| Dimensions | Machine length | mm | 2910 | 3020 | 3020 |

| Machine width | mm | 2015 | 2015 | 2015 | |

| Machine height | mm | 2065 | 2065 | 2065 | |

| Machine weight | Kg | 5350 | 5350 | 5350 | |

| Other | Floor area | mm | 4070x3530 | 4180x3530 | 4180x3530 |

| Electricity requirements | Kva | 53 | 53 | 53 |