Production

-

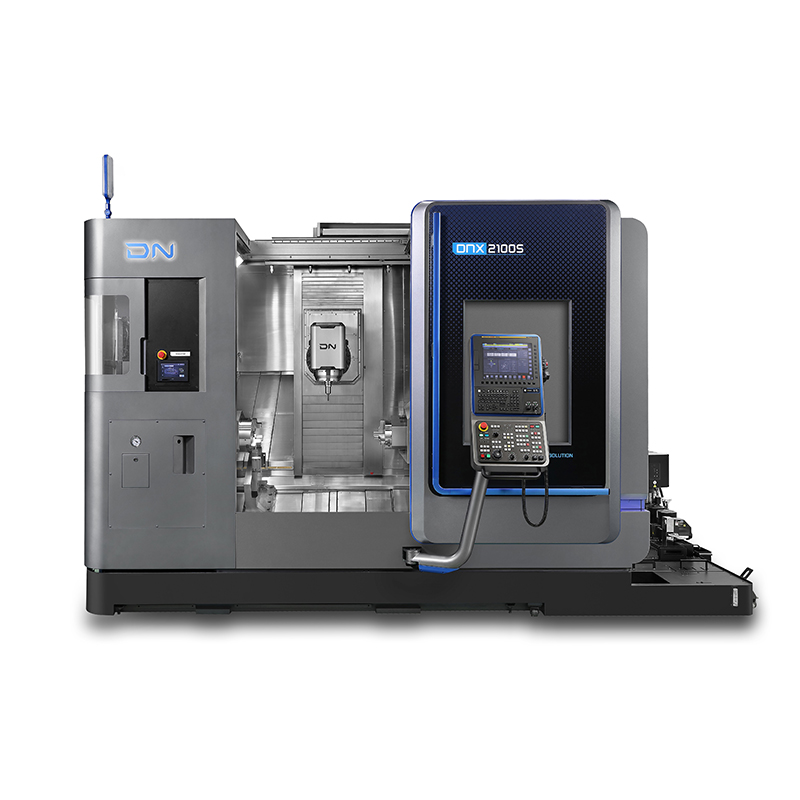

Mylas

VG series

Product Details 1.Design of solid U/V axis casting to provide stable cutting accuracy. 2.Stainless steel working surface, hardness reaches HRC 50°. 3.High response AC servo motor to ensure accuracy. 4.Increase the span design of the machine base. High rigidity casting design, using finite ...

Description

marker

Product Details

1.Design of solid U/V axis casting to provide stable cutting accuracy.

2.Stainless steel working surface, hardness reaches HRC 50°.

3.High response AC servo motor to ensure accuracy.

4.Increase the span design of the machine base.

High rigidity casting design, using finite element analysis to design the machine body, with the best support (RIB) design to support the column, reduce the deformation caused by casting stress, to achieve the basic elements of high precision.

Product Parameters

| model | VG400 | VG500 | VG600 |

| Transmission system | 5 axis AC servo motor | 5 axis AC servo motor | 5 axis AC servo motor |

| XY axis travel | 400 x 300 mm | 500 x 300 mm | 600 x 400 mm |

| Maximum processing tilt | ±22°/100 мм (wide angle eye mask and attachment) | ±22°/100 мм(wide angle eye mask and attachment) | ±26°/100 мм (wide angle eye mask and attachment) |

| UV axis travel | 80 x 80 mm | 80 x 80 mm | 120 x 120 mm |

| Covered area | 2100 x 2230 x 2200 mm | 2200 x 2450 x 2200 mm | 2550 x 2600 x 2200 mm |

| Z axis travel | 220 mm | 220 mm | 310 mm |

| Machine weight (mechanical, electrical and water) | 2700 kg | 3500 kg | 4400 kg |